Wheat grain dryer

Wheat grain dryer is an agricultural machinery equipment, mainly used for drying grain crops such as wheat, corn, and rice. It has the advantages of good quality, fast speed, and energy saving, which can help farmers solve the problem of drying grain and improve the quality of grain.

Wheat grain dryer Introduction

Wheat grain dryer is an agricultural machinery equipment, mainly used for drying grain crops such as wheat, corn, and rice. It has the advantages of good quality, fast speed, and energy saving, which can help farmers solve the problem of drying grain and improve the quality of grain. The working principle of wheat grain dryer is to kill insect eggs through high temperature treatment and completely solve the problem of grain drying. This equipment adopts a rotary heating device, which can generate a large amount of hot air in a short time, thereby effectively drying grain and ensuring the quality and safe storage of grain.

Function of wheat grain dryer

Improved Grain Quality

The drying process effectively removes moisture, impurities, and pests from wheat, significantly enhancing the quality and taste of the grain. The presence of moisture and impurities can reduce the storage stability and nutritional value of the grain, but the dryer effectively addresses these issues.

Reduced Losses

Crops like wheat are vulnerable to moisture, mold, and pest infestations, which can lead to high loss rates. Dryers can promptly process wet crops, preventing mold and pest issues, thus reducing food loss caused by these problems.

Increased Harvest Yield

In humid conditions, the weight of crops like wheat increases, but this weight gain is primarily due to moisture rather than actual grain. Dryers remove moisture, helping to maintain the original weight of the crops and effectively increasing the harvest yield.

Enhanced Storage Capacity

Wet crops can create a humid environment in storage facilities, leading to decreased storage capacity. Dryers eliminate moisture, improving the storage capacity of warehouses, allowing grain to be stored safely and for longer periods.

Reduced Moisture Content

The primary function of wheat dryers is to reduce the moisture content in crops to suitable levels for storage, transportation, and processing. Lowering moisture content helps enhance the stability and shelf life of wheat.

Energy Savings

Compared to traditional natural drying methods, wheat dryers effectively save energy. The heat and energy required for drying are significantly less than those needed for natural drying, while also achieving higher drying efficiency.

Increased Market Value

The quality of crops like wheat improves through the drying process, subsequently increasing their market value. This enhancement is crucial for farmers and grain processing enterprises.

Intelligent Control

Modern wheat dryers feature intelligent control functions. Equipped with smart sensors and control systems, they allow for real-time monitoring and adjustments of the drying process, ensuring consistency and stability while preventing over-drying or under-drying.

Improved Drying Efficiency

Dryers can dry large quantities of grain in a short period, producing high-quality grains with better taste. This significantly boosts drying efficiency while saving on labor and time costs.

The structure of wheat grain dryer

Heat Source System

This is the core part of the dryer, responsible for generating hot air. Common heat sources include coal, natural gas, and diesel, but electric heating or microwave heating can also be used. The heat source system provides the necessary thermal energy for the drying process.

Drying Tower (or Drying Chamber)

This is the main body of the dryer, typically designed in a cylindrical shape, featuring multiple flip plates and nozzles that ensure even heating of the wheat while preventing burning or scorching. The drying chamber is the essential part of a mobile grain dryer, usually constructed from welded steel plates, which offer excellent sealing and durability.

Fan System

This system is responsible for delivering air into the dryer and providing the hot air needed for drying. The fan system is a crucial component of the entire drying machine, ensuring the circulation of hot air.

Dehumidification System

This system removes moisture from the dryer through dehumidification devices such as condensers and heat exchangers, ensuring effective drying. The dehumidification system primarily functions to expel excess moisture, preventing excessive buildup that could hinder the drying process.

Dust Removal System

This system filters dust and impurities generated during the drying process, ensuring the air remains clean and hygienic. The dust removal system is responsible for collecting and managing dust produced during drying, maintaining a clean working environment.

Ventilation System

This system directs hot air into the drying tower (or drying chamber) while simultaneously expelling the dried air from the dryer.

Control System

This system manages the operation of the dryer, including controlling temperature, humidity, and time. The control system is a vital component, providing real-time monitoring and adjustment of the operational status of various parts to ensure stability and efficiency during the drying process.

Conveying System

This system transports the dried wheat to the next processing or storage stage. It includes the feed inlet, discharge outlet, and grain conveyor, ensuring the continuous movement of grain throughout the drying process.

Key Advantages of Wheat Grain Dryer

Improving Drying Efficiency

The dryer can efficiently dry large quantities of wheat and other grains in a short period, significantly enhancing drying efficiency compared to traditional sun-drying methods, and saving time.

Ensuring Drying Quality

With a well-designed interior, the dryer ensures even heating of wheat and other grains, preventing overheating or uneven drying. This guarantees the quality of the dried grains. Additionally, the dryer can precisely control temperature and time based on the specific characteristics and requirements of different grains, achieving optimal drying results.

Reducing Losses

In natural sun-drying, wheat and other grains are vulnerable to weather conditions and pests, leading to increased losses. The dryer operates in a controlled environment, shielding the grains from these adverse factors, thereby reducing losses.

Enhancing Storage Stability

The dryer reduces the moisture content in wheat and other grains to an appropriate level, thereby improving the stability of the stored grains. This helps extend the shelf life of the grains and reduces losses due to mold or pests.

Energy Efficiency and Environmental Protection

Modern dryers typically use advanced energy-saving technologies and materials, reducing energy consumption and emissions. Moreover, the dryer can be intelligently controlled based on actual needs, preventing energy waste and contributing to green production and sustainable development.

Reducing Labor Intensity

The high degree of automation in dryers reduces the need for manual operation and intervention, lowering labor intensity. This is crucial for enhancing production efficiency and reducing labor costs.

Increasing Market Value

Wheat and other grains that have been dried in a dryer exhibit better quality and taste, meeting the market's demand for high-quality agricultural products. This increases the market value of the agricultural products and boosts farmers' incomes.

Strong Adaptability

The dryer is adaptable to the drying needs of different types and moisture levels of wheat and other grains. Additionally, the dryer can be flexibly configured and adjusted based on production environments and conditions to meet the specific needs of different users.

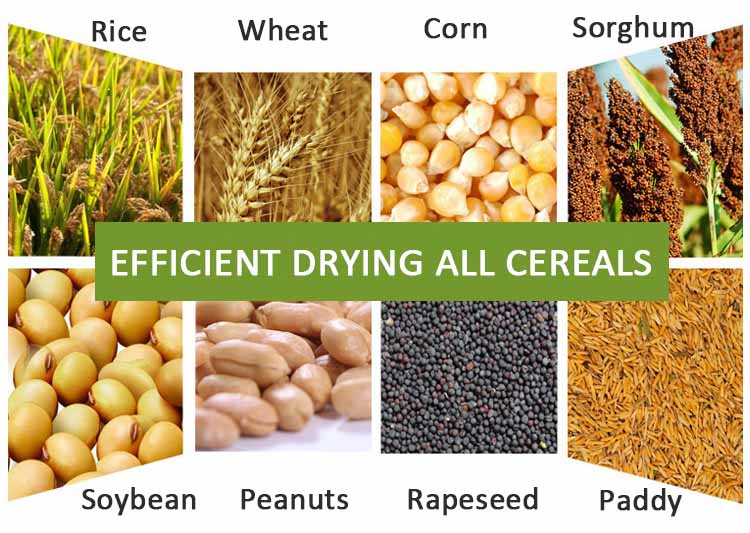

Application of Wheat grain dryer

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

Technical parameters of Wheat grain dryer

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.