vertical paddy dryer

A vertical paddy dryer is a type of equipment used for drying paddy rice. It features a vertical design where the paddy is fed from the top, passing through multiple drying layers as it descends, coming into full contact with hot air to achieve uniform drying.

vertical paddy dryer Introduction

A vertical paddy dryer is a type of equipment used for drying paddy rice. It features a vertical design where the paddy is fed from the top, passing through multiple drying layers as it descends, coming into full contact with hot air to achieve uniform drying.

Features of vertical rice dryer

Vertical Structure

The vertical design requires a smaller footprint, making it suitable for spaces with limited area. The paddy descends layer by layer through gravity, passing through each drying layer sequentially.

Multi-layer Drying

It has multiple drying layers inside, with each layer providing hot air for drying. This ensures that the paddy is adequately dried at different stages, guaranteeing effective drying.

Hot Air Circulation

The hot air circulation system ensures that hot air is evenly distributed across all drying layers, ensuring uniform drying of the paddy. Hot air is typically provided by a hot air furnace or heat exchanger.

Automated Control

Equipped with an automated control system, it can monitor and adjust temperature and humidity in real-time during the drying process, ensuring precision and stability in drying.

High Energy Efficiency

The hot air circulation and heat recovery system enhance energy utilization efficiency, reducing energy consumption and lowering drying costs.

Strong Adaptability

Suitable for drying various grains, not just limited to paddy rice, but also including wheat, corn, rice, barley, and more.

Safety and Reliability

Equipped with safety protection devices such as fire prevention equipment and high-temperature alarm systems, ensuring safety during the drying process.

Easy Maintenance

Designed for ease of cleaning and maintenance, reducing downtime and increasing operational efficiency.

Features of vertical rice dryer

Feeding System

Used to feed the paddy into the top inlet of the dryer. It typically includes a feed hopper and conveying devices (such as a belt conveyor or screw conveyor) to ensure the paddy enters the dryer evenly.

Drying Tower

The core drying area, consisting of multiple drying layers or sections. The paddy descends layer by layer from the top, fully contacting with hot air as it passes through each layer, achieving step-by-step drying.

Hot Air System

Includes a hot air furnace or heat exchanger to generate hot air, which is then transported into the drying tower through ducts. The hot air system also includes fans to ensure the circulation of hot air within the drying tower.

Circulation Fan

Ensures the circulation of hot air within the drying tower, evenly distributing hot air to all drying layers to ensure uniform drying of the paddy.

Moisture Exhaust System

Used to expel the moist air generated during the drying process. It typically includes exhaust fans and ducts to maintain appropriate humidity levels within the drying tower, enhancing drying efficiency.

Control System

An automated control system that includes temperature sensors, humidity sensors, and a control panel. This system monitors and adjusts temperature and humidity parameters during the drying process to ensure precision and stability.

Discharging System

Used to discharge the dried paddy from the bottom of the drying tower. It typically includes a discharge outlet and conveying devices (such as a screw conveyor or belt conveyor) to ensure the smooth transfer of dried paddy to the next processing stage.

Frame Structure

Provides support and protection for the dryer's components, usually made of durable metal materials to ensure the equipment's stability and durability.

Safety Devices

Includes fire prevention equipment and high-temperature alarm devices to ensure safety during the drying process.

Advantages of vertical rice dryer

Small Footprint

The vertical design requires less floor space, making it suitable for locations with limited space, thereby improving land utilization.

High Drying Efficiency

Hot air passes through the grain layers from bottom to top, ensuring uniform heating of the grains, resulting in effective and rapid drying.

High Energy Utilization

Through the hot air circulation system and heat exchanger, heat from the hot air can be recovered and reused, significantly improving energy utilization efficiency, reducing energy consumption, and lowering operating costs.

Uniform Drying

The multi-layer drying structure ensures that grains are evenly dried at different stages, preventing over-drying or under-drying in specific areas, and enhancing drying quality.

Automated Control

Equipped with advanced automated control systems, it can monitor and adjust parameters such as temperature and humidity in real-time, ensuring precision and stability in the drying process and reducing human error.

Strong Adaptability

Suitable for drying various grains, not just limited to paddy rice, but also including wheat, corn, rice, barley, and more.

Easy Maintenance

Designed for easy cleaning and maintenance, reducing downtime and increasing operational efficiency.

Safety and Reliability

Equipped with comprehensive safety protection devices, such as fire prevention equipment and high-temperature alarm systems, ensuring safety during the drying process.

Labor Saving

High level of automation and simple operation reduce reliance on manual labor, lowering labor costs.

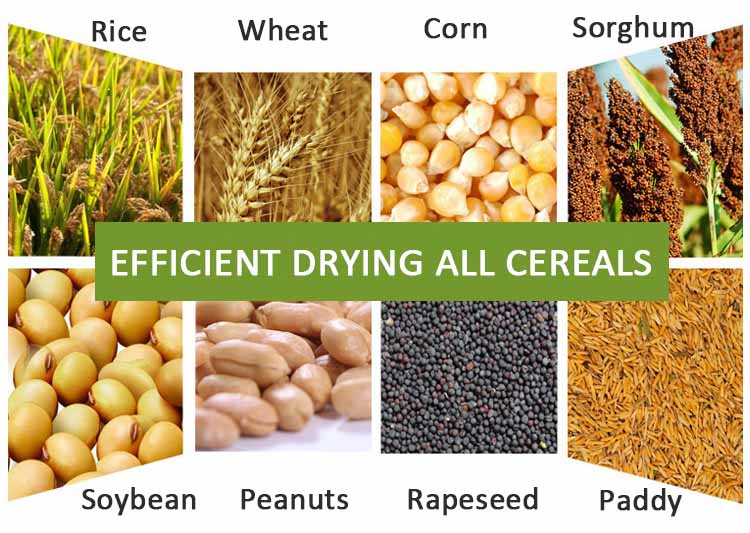

vertical paddy dryer Application

The Grain dryer machine is suitable for efficiently drying all cereals,grains,beans,and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

vertical paddy dryer Technical Parameter

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.