vertical grain dryer

A vertical grain dryer is a drying device designed in a vertical orientation. Typically constructed from metal or plastic, it features ventilation holes allowing air to flow through the grains.

vertical grain dryer Introduction

A vertical grain dryer is a drying device designed in a vertical orientation. Typically constructed from metal or plastic, it features ventilation holes allowing air to flow through the grains. Grains are usually placed inside this container and dried by heating or ventilation to remove moisture, achieving the purpose of drying. Such dryers are typically suitable for small-scale grain drying, such as household or small farm use.

Features of vertical grain dryer

Vertical Design

The vertical orientation allows for efficient airflow through the grains, aiding in the drying process.

Compact Size

Vertical dryers often have a smaller footprint compared to horizontal models, making them suitable for smaller spaces or operations with limited area.

Versatility

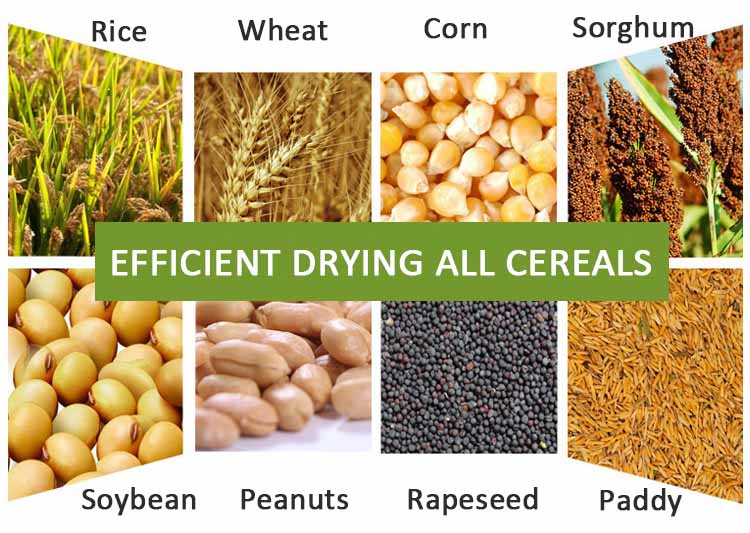

These dryers can be used for a variety of grains, including rice, wheat, corn, and more.

Adjustable Settings

Many vertical grain dryers come with adjustable temperature and airflow settings, allowing users to customize the drying process based on the type of grain and desired moisture level.

Energy Efficiency

Some models are designed to be energy-efficient, using technologies such as heat recovery systems or efficient fans to reduce energy consumption during the drying process.

Ease of Use

Vertical dryers are typically designed for ease of use, with features such as user-friendly controls and easy access for loading and unloading grains.

Durability

High-quality construction materials and robust design ensure durability and longevity, even under heavy use.

Safety Features

Many models are equipped with safety features such as temperature sensors, automatic shut-off mechanisms, and fire suppression systems to ensure safe operation.

Structure of vertical grain dryer

Main frame

The primary structural framework that supports the entire dryer, usually constructed of metal.

Drying chamber

A space designed to hold grains, often a vertical container with ventilation holes.

Ventilation system

Includes fans, ventilation holes, and ducts to guide air flow through the grains, accelerating the drying process.

Heating system

Typically heating elements or burners that provide thermal energy to heat the air and expedite moisture evaporation.

Control system

Controls the operation of the dryer, including temperature control, airflow settings, etc.

Grain unloading device

Used to unload dried grains from the dryer, usually a bottom discharge port or conveyor system.

Safety devices

Such as temperature sensors, automatic shutdown mechanisms, etc., to ensure safe operation of the dryer.

Advantages of Vertical Grain Dryer

Efficient Use of Space

Their vertical design allows for efficient use of space, making them suitable for operations with limited area.

Improved Airflow

Vertical orientation facilitates better airflow through the grains, enhancing the drying process and reducing drying time.

Versatility

They can handle various types of grains, including rice, wheat, corn, etc., making them versatile for different agricultural contexts.

Energy Efficiency

Many vertical dryers are designed to be energy-efficient, incorporating features like heat recovery systems or efficient fans to reduce energy consumption.

Easy Loading and Unloading

The vertical design often allows for easier loading and unloading of grains, streamlining the operation.

Customizable Settings

Most models come with adjustable temperature and airflow settings, allowing users to customize the drying process based on grain type and desired moisture level.

Durability

High-quality construction materials and robust design ensure durability and longevity, even under heavy use.

Safety Features

Many vertical dryers are equipped with safety features such as temperature sensors, automatic shutdown mechanisms, and fire suppression systems to ensure safe operation.

vertical grain dryer Application

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

vertical grain dryer Technical Parameter

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.