Soybean grain dryer

Soybean grain dryer is a mechanical equipment specially used for drying soybean and other grains. It adopts the form of hot air drying box, which can generate a large amount of hot air in a short time, kill insect eggs through high temperature treatment, and completely solve the problem of grain drying.

Soybean grain dryer Introduction

Soybean grain dryer is a mechanical equipment specially used for drying soybean and other grains. It adopts the form of hot air drying box, which can generate a large amount of hot air in a short time, kill insect eggs through high temperature treatment, and completely solve the problem of grain drying. This dryer is particularly suitable for drying grain crops such as soybeans, which can improve the economic value of grain. The design and manufacture of soybean grain dryer takes into account the needs and characteristics of grain drying to ensure that the grain can maintain good quality and economic value during the drying process.

Soybean grain dryer Features

Efficient Moisture Removal

The soybean dryer effectively removes excess moisture from soybeans, enhancing their storage quality and safety. This is the most fundamental and core function of the dryer.

Reduced Mold and Spoilage

By rapidly drying soybeans, the dryer significantly lowers the risk of mold and spoilage during storage, thereby extending the shelf life of the soybeans.

Improved Yield and Quality

Post-drying, soybeans exhibit improved yield and quality during processing, which in turn increases their economic value. Although the term "yield" might not be entirely accurate for soybeans (as they aren't rice), it can be understood that dried soybeans have a higher utilization rate and product quality in subsequent processes such as oil extraction.

Lower Production Costs and Labor Intensity

The soybean dryer, with its high degree of automation, requires minimal human operation, significantly reducing production costs and labor intensity. Additionally, the dryer operates independently of weather conditions, avoiding the inconveniences and losses associated with traditional sun-drying methods due to weather changes.

Uniform Drying

During the drying process, the soybean dryer repeatedly tumbles the soybeans, ensuring full contact with the hot air, which allows moisture to evaporate, resulting in uniform drying. This uniformity in drying contributes to the overall quality of the soybeans.

Energy Efficiency and Environmental Protection

Modern soybean dryers typically use hot air drying technology, which offers energy-saving and environmentally friendly benefits. This not only helps reduce production costs but also aligns with current societal demands for sustainable development.

Wide Application Range

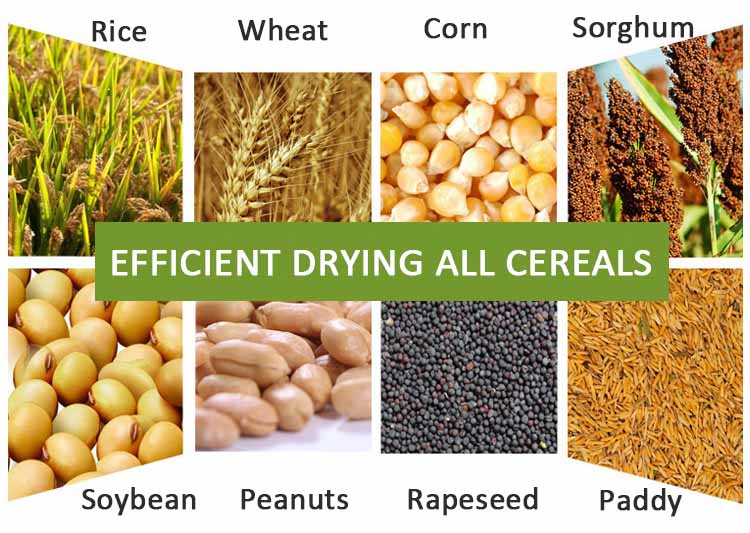

The soybean dryer is not only suitable for drying soybeans but can also be used for drying other grains and oilseeds, such as wheat, corn, rice, and peanuts. This broadens the dryer’s application potential in agriculture and the food processing industry.

The structure of soybean grain dryer

Heating System

As the core component of the dryer, the heating system transfers heat to the drying process by burning fuels such as coal or biomass, or through electric heating. This provides the necessary heat source for grain drying.

Conveying System

Comprised of conveyor belts, pumps, motors, and other parts, the conveying system is responsible for transporting wet soybeans (or other grains) into the drying chamber and collecting the dried soybeans afterward. This system ensures the smooth flow of grains throughout the drying process.

Control System

The control system is a critical part of the dryer, consisting of sensors for temperature, humidity, and pressure, along with control instruments. It monitors and regulates the dryer’s operation, ensuring the stability and effectiveness of the drying process. The control system automatically adjusts drying temperature and humidity according to preset parameters to achieve optimal drying results.

Drying Chamber

As the main part of the dryer, the drying chamber typically includes air inlets, heaters, fans, and exhaust outlets. It introduces hot air into the chamber, ensuring full contact between the hot air and the grain, allowing moisture to evaporate. The design and structure of the drying chamber directly impact the drying effectiveness.

Air Supply System

Another crucial component of the dryer, the air supply system, is mainly responsible for drawing air into the drying chamber to accelerate the drying process. This system usually consists of a centrifugal fan and air ducts, with the centrifugal fan playing a key role in drawing external air and pressurizing it into the drying chamber.

Discharge System

This system discharges the dried soybeans from the dryer and can be equipped with dust removal devices to filter out dust and other impurities as needed.

Other Auxiliary Components

Some advanced dryers may also be equipped with features such as automatic feeding, automatic discharging, and automatic cleaning to enhance drying efficiency and reduce labor costs.

The main advantages of soybean grain dryer

High Drying Efficiency

The soybean dryer quickly removes excess moisture from soybeans, enhancing drying efficiency and saving time. Its tower-like design ensures even heating and better grain flow, which accelerates the drying process.

Superior Drying Quality

Using low-temperature, constant-temperature, and fully-covered drying methods, the clean heat source ensures thorough drying of the soybeans without compromising their quality. The dried soybeans achieve an average moisture content of less than 12%, offering a more uniform result than natural sun drying.

Low Operating Costs

The soybean dryer operates at relatively low costs. By using efficient gasification furnaces as a heat source, it reduces coal consumption and lowers drying costs. Additionally, the entire system requires minimal manpower, significantly reducing labor costs.

Easy Operation

The soybean dryer features a high level of automation, making it easy to operate. Once the relevant parameters are set, the equipment runs automatically with minimal manual intervention required.

High Stability

Constructed with high-quality materials and advanced manufacturing processes, the soybean dryer offers excellent stability and reliability. It maintains consistent operation during the drying process, ensuring uniform and reliable drying results.

Wide Applicability

The soybean dryer is suitable not only for drying soybeans but also for other grains, oilseeds, and materials. This versatility makes it valuable across agriculture and food processing industries.

Weather Independence

Unlike traditional sun drying methods, the soybean dryer operates independently of weather conditions, enabling drying operations in any weather, thereby increasing production efficiency and stability.

Energy-Efficient and Environmentally Friendly

Modern soybean dryers are designed with energy-saving and eco-friendly principles. They utilize technologies like hot air drying and waste heat recovery, reducing energy consumption and emissions, aligning with sustainable development goals.

Application of Soybean grain dryer

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

Technical parameters of Soybean grain dryer

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.