soybean drying tower

A soybean drying tower is a piece of equipment used to dry soybeans. It typically features a tower-like structure and is designed for continuous flow. By controlling temperature, humidity, and airflow, it reduces the moisture content of freshly harvested soybeans to safe storage levels

soybean drying tower Introduction

A soybean drying tower is a piece of equipment used to dry soybeans. It typically features a tower-like structure and is designed for continuous flow. By controlling temperature, humidity, and airflow, it reduces the moisture content of freshly harvested soybeans to safe storage levels, preventing the growth of mold and other harmful microorganisms. Soybean drying towers play a crucial role in agricultural production and grain processing, contributing to the improvement of soybean quality, extension of shelf life, and reduction of losses during grain storage.

Characteristics of soybean drying tower

Efficient and Fast Drying

Soybean drying towers employ continuous flow design to quickly and continuously process large quantities of soybeans, thereby enhancing production efficiency.

Precise Temperature and Humidity Control

They regulate the environmental conditions during drying with precise temperature and humidity control systems, ensuring uniform heating and appropriate drying of soybeans.

Quality Preservation

Proper drying helps maintain the color, texture, and nutritional value of soybeans, preventing the growth of mold and bacteria due to moisture.

Energy-saving and Environmentally Friendly

Modern soybean drying towers often feature energy-saving designs and efficient heat utilization systems, reducing energy consumption and environmental pollution.

Flexible Adjustment

They can adjust drying parameters flexibly according to the needs of different regions, climates, and soybean varieties to achieve personalized drying treatment.

Automation Control

Equipped with advanced automation control systems, they intelligently monitor and adjust the drying process, enhancing operational convenience and stability.

Multiple Safety Protections

The equipment is equipped with multiple safety features such as overload protection, overheat protection, and emergency shutdown, ensuring safe and reliable operation.

Wide Applicability

Besides soybeans, soybean drying towers are also suitable for drying other grains such as maize, wheat, etc.

Extended Shelf Life

By effectively removing moisture from soybeans, they can extend their shelf life, reducing losses during storage.

The structure of soybean drying tower

Tower Main Body

This is the core part of the drying tower, typically including the upper mixed-flow drying section, lower mixed-flow drying section, upper slow material bin, lower slow material bin, and lifting conveying device.

Automatic Temperature Control Device

It is used to monitor the hot air temperature, grain temperature, and grain moisture content in real time to ensure the stability and efficiency of the drying process.

Hot Air Furnace

Acts as the heat source, transforming air into clean hot air entering the drying section through combustion and heat exchange, avoiding grain contamination.

Vibrating Screen

Used for cleaning grains if necessary.

Grain Loading Machine

Used to load grains into the drying tower.

Feeding Section, Heating Layer, Hot Air Layer, and Discharging Section

These parts constitute the main structure of the soybean conditioning tower, with the heating layer arranged in a staggered manner using elliptical tubes to improve heat conduction and material flow.

Storage Section, Drying Section, Soaking Section, Cooling Section, and Grain Discharging Section

In a continuous mixed-flow tower body, these parts work together to achieve grain drying and discharging.

Advantages of soybean drying tower

Efficient and Fast Processing

Soybean drying towers process large quantities of soybeans quickly and continuously, enhancing production efficiency.

Quality Preservation

They maintain the color, texture, and nutritional value of soybeans through precise temperature and humidity control, preventing the growth of mold and bacteria due to moisture.

Energy-saving and Environmentally Friendly

Modern soybean drying towers feature energy-saving designs and efficient heat utilization systems, reducing energy consumption and environmental pollution.

Flexible Adjustment

Operators can adjust drying parameters according to the specific needs of different regions, climates, and soybean varieties to achieve personalized drying treatment.

Automation Control

Equipped with advanced automation control systems, they intelligently monitor and adjust the drying process, enhancing operational convenience and stability.

Multiple Safety Protections

These towers are equipped with multiple safety features such as overload protection, overheat protection, and emergency shutdown, ensuring safe and reliable operation.

Wide Applicability

Soybean drying towers are suitable not only for soybeans but also for drying other grains such as maize, wheat, etc.

Extended Shelf Life

By effectively removing moisture from soybeans, they can extend their shelf life, reducing losses during storage.

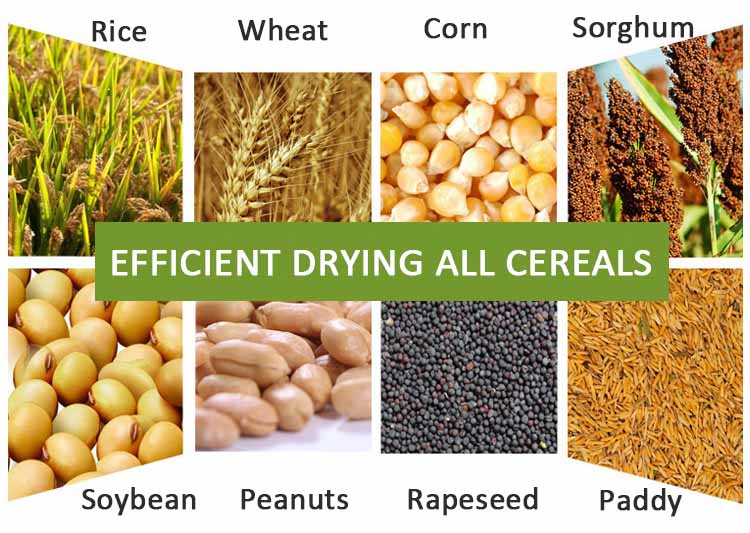

Application of soybean drying tower

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

Technical parameters of soybean drying tower

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.