soybean dryer

A soybean dryer, also known as a soybean drying machine, is an agricultural machine used to reduce the moisture content in soybeans. It removes excess moisture from soybeans through heating and ventilation, bringing the water content down to a safe level for storage. This is crucial for preventing mold, germination, or rot during storage.

soybean dryer Introduction

A soybean dryer, also known as a soybean drying machine, is an agricultural machine used to reduce the moisture content in soybeans. It removes excess moisture from soybeans through heating and ventilation, bringing the water content down to a safe level for storage. This is crucial for preventing mold, germination, or rot during storage.

Main features of soybean dryer

High Efficiency and Energy Saving

It uses advanced drying technology to effectively reduce the moisture content of soybeans in a short amount of time.

Automated Control

Equipped with an automated control system that can automatically adjust drying parameters based on the initial and desired final moisture content of the soybeans.

Temperature Regulation

The drying temperature can be adjusted to suit different types and conditions of soybeans.

Humidity Control

It ensures that the soybeans are not over-dried or under-dried by controlling the humidity levels.

Even Drying

It ensures even heat distribution during the drying process to prevent local overheating or uneven drying.

Easy to Operate

The user interface is friendly, and the operation is simple, making it easy for farmers and operators to use.

Strong Adaptability

Suitable for soybean drying operations of different scales, from small farms to large grain processing plants.

Easy Maintenance

The design takes into account the convenience of maintenance, making it easy to inspect and maintain regularly.

Environmental Protection

It uses environmentally friendly drying technology to reduce environmental impact.

Versatility

Some dryers are designed to accommodate the drying needs of various grains and agricultural products.

The structure of soybean dryer

Drying Tower

The core part of the dryer where soybeans are dried by hot air passing through the tower.

Heat Source System

Provides the thermal energy required for drying, which can be from various sources such as fuel oil, natural gas, electricity, or biomass energy.

Ventilation System

Includes fans and ducts that transport hot air through the drying tower, ensuring even distribution of hot air.

Conveying System

Equipment that transports soybeans to the drying tower, typically including conveyor belts, bucket elevators, or screw conveyors.

Control System

An automated control system that monitors and regulates the drying process to ensure the desired drying effect is achieved.

Humidity and Temperature Sensors

Used to monitor the moisture content of the soybeans and the temperature inside the drying tower in real-time, feeding back to the control system.

Dust Removal System

Removes dust generated during the drying process, usually including a dust collector and exhaust ducts.

Cooling Section

In some dryers, there is a cooling section to reduce the temperature of the dried soybeans, making them more suitable for storage.

Discharge System

Equipment that discharges the dried soybeans from the drying tower, which may include discharge screws or conveyor belts.

Frame Structure

The steel structure that supports the entire dryer, ensuring the stability of the equipment.

Safety Devices

Include emergency stop buttons, overheating protection, fault alarms, and other safety measures.

Insulation Material

Used for insulation of the drying tower and hot air ducts to reduce heat loss.

Advantages of soybean dryer

Improved Efficiency

The automated drying process significantly increases efficiency and reduces the demand for manual labor.

Even Drying

It ensures even heat distribution for the soybeans, preventing local overheating or uneven drying, thus maintaining the quality of the soybeans.

Flexibility

Drying parameters can be adjusted to accommodate different types and moisture levels of soybeans.

Energy Saving

Utilizes efficient thermal energy technology to reduce energy consumption.

Reduced Loss

Effective control of the drying process minimizes losses during soybean drying.

Easy Operation

The user interface is friendly, and the operation is simple, allowing farmers and operators to quickly master its use.

Easy Maintenance

The design considers the convenience of maintenance, facilitating routine inspections and maintenance.

Strong Adaptability

Suitable for farms and grain processing plants of different sizes, meeting a variety of drying needs.

Environmental Protection

Reduces environmental pollution associated with natural sun drying.

Enhanced Storage Safety

Lowering the moisture content of soybeans reduces the risk of mold and rot during storage.

Quality Improvement

Proper drying can enhance the market quality and economic value of soybeans.

Automated Control

Allows for remote monitoring and control, improving management efficiency.

Versatility

Some models of dryers can accommodate the drying needs of various agricultural products.

soybean dryer Application

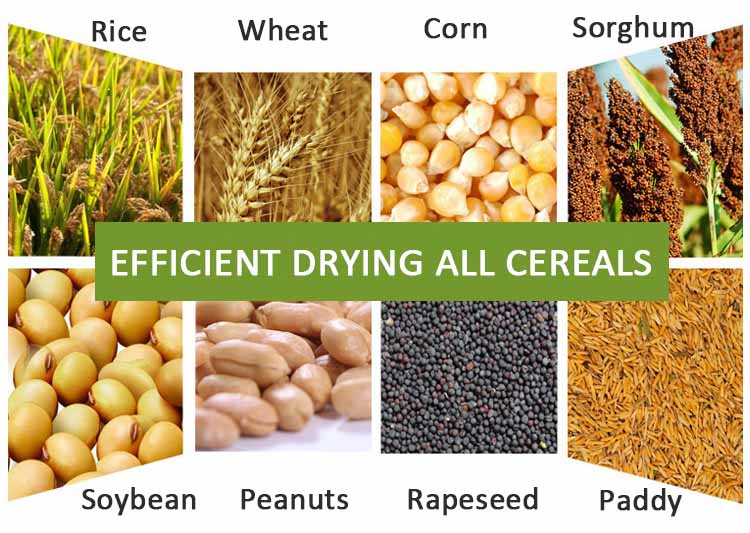

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

soybean dryer Machine Technical Parameter

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.