sorghum grain dryer

The sorghum grain dryer is a device specially used to dry and dehydrate freshly harvested sorghum. Its working principle is to use heat to dry the sorghum to a safe moisture content, so that it can be transported, processed and stored.

sorghum grain dryer Introduction

The sorghum grain dryer is a device specially used to dry and dehydrate freshly harvested sorghum. Its working principle is to use heat to dry the sorghum to a safe moisture content, so that it can be transported, processed and stored. This equipment can increase the speed of sorghum harvesting, shorten the drying time, and effectively improve the quality of sorghum. In addition, some sorghum dryers are also equipped with a mobile chassis, which can be towed by a vehicle and moved at will, reducing transportation costs and further improving work efficiency.

Functional characteristics of sorghum grain dryer

Rapid Moisture Removal

By utilizing heat sources such as hot air, solar energy, or infrared radiation, the moisture in sorghum is quickly evaporated, reducing its moisture content to meet safe storage standards.

Improved Storage Stability

Once dried, the moisture content of the sorghum is significantly reduced, minimizing issues like mold growth and sprouting, which enhances storage stability and extends the storage period.

Enhanced Processing Quality

The drying process can effectively improve the quality of sorghum, resulting in a brighter color and better taste, which is beneficial for subsequent processing and sales.

Increased Production Efficiency

Sorghum dryers can significantly shorten drying times and increase production efficiency. For large-scale sorghum farmers and processing enterprises, this helps reduce post-harvest waiting times and accelerates capital turnover.

Reduced Labor Intensity

With a high level of automation, the sorghum dryer reduces the need for manual turning and drying, thereby lowering labor intensity and boosting production efficiency.

Minimized Losses

By drying the sorghum, losses caused by adverse weather conditions (such as rain or humidity) are minimized, preventing mold growth and sprouting, which in turn protects the farmers' economic interests.

Multiple Drying Methods Available

The sorghum dryer offers various drying options based on actual needs, including natural air drying, solar drying, hot air drying, and infrared drying, to accommodate different production environments and requirements.

Structural composition of sorghum grain dryer

Feeding System

The feeding system is responsible for conveying the sorghum into the dryer. It may include equipment such as feed hoppers, conveyors, or elevators, ensuring that the sorghum enters the drying process smoothly.

Drying System

- Hot Air Furnace: This is the equipment that provides the necessary heat for drying. It generates thermal energy by burning fuels like coal, wood, or diesel, which is then converted into hot air.

- Fans: This includes both blower fans and induced draft fans. The blower fan enhances the combustion efficiency of the hot air furnace by increasing the air supply, while the induced draft fan continuously extracts the moist hot steam after drying, keeping the internal environment dry and maintaining the proper temperature.

- Heat Exchanger: Positioned between the hot air furnace and the drying chamber, the heat exchanger transfers heat to improve thermal energy efficiency.

- Hot Air Ducts: These ducts connect the hot air furnace to the drying chamber, transporting hot air into the chamber.

- Drying Chamber: The sorghum undergoes the drying process inside the drying chamber. The internal design of the chamber is typically optimized to ensure effective contact between the hot air and the sorghum, enabling rapid and uniform drying.

- Discharge System: The discharge system removes the dried sorghum from the dryer. Dust removal devices can also be installed as needed to filter out dust and other impurities.

Control System

The control system manages the operation of the hot air furnace, fans, heat exchanger, and other equipment. It automatically adjusts the drying process according to preset temperature and humidity parameters, ensuring that the sorghum receives the appropriate drying treatment while enhancing efficiency and stability.

Additional Auxiliary Components

Depending on the specific model and brand of the dryer, there may be additional features such as automatic feeding, automatic discharging, and automatic cleaning functions to improve drying efficiency and reduce labor costs.

The main advantages of sorghum grain dryer

Enhancing Drying Efficiency

The sorghum dryer employs advanced drying technology to rapidly evaporate moisture from the sorghum, significantly increasing drying efficiency. Compared to traditional sun-drying methods, the dryer can process large quantities of sorghum in a short period, reducing drying time and boosting production efficiency.

Ensuring Drying Quality

The dryer precisely controls drying parameters such as temperature, humidity, and time, ensuring that the sorghum is evenly heated throughout the drying process. This prevents issues like localized overheating or insufficient drying, thereby preserving the sorghum’s original quality and taste. The dried sorghum is bright in color and full in grain, which is beneficial for subsequent storage and processing.

Reducing Grain Loss

In natural sun-drying, sorghum is susceptible to weather conditions, pests, and other factors that can lead to grain loss. The dryer mitigates these risks by operating in an enclosed environment, protecting the sorghum from external threats and reducing losses. Additionally, the dryer allows for precise control based on the actual condition of the sorghum, preventing losses due to over-drying or under-drying.

Lowering Labor Intensity

Using a sorghum dryer significantly reduces the labor intensity for farmers and lowers labor costs. Farmers only need to load the sorghum into the dryer and set the parameters; the dryer then automatically completes the drying process, eliminating the need for manual turning and constant supervision.

Improving Economic Benefits

By enhancing drying efficiency and quality, reducing grain loss, and lowering labor intensity, the sorghum dryer can substantially increase farmers' economic returns. The dried sorghum has better storage stability and processing quality, which helps increase its market value.

Wide Applicability

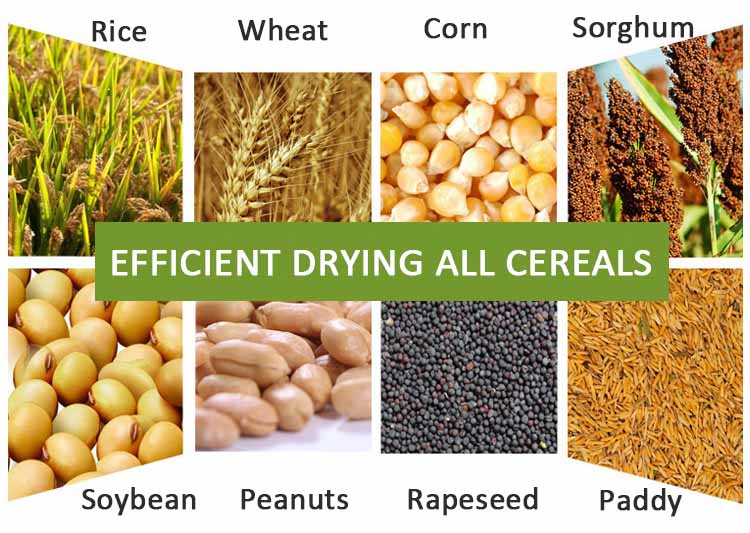

The sorghum dryer is not only suitable for drying sorghum but can also be used for drying rice, wheat, peanuts, corn, and various other grains and economic crops. This wide applicability makes the dryer highly valuable in agricultural production.

Energy-Saving and Environmentally Friendly

Modern sorghum dryers typically use advanced energy-saving technologies and environmentally friendly materials, ensuring effective drying while reducing energy consumption and environmental pollution. For example, the use of low-temperature, high-volume automatic circulation drying technology can reduce energy consumption, while the use of eco-friendly materials minimizes environmental impact.

Application of sorghum grain dryer

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

Technical parameters of sorghum grain dryer

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.