sorghum dryer

A sorghum dryer is a specialized mechanical device designed for drying sorghum and other grains. Through specific processes and structural designs, it efficiently removes moisture from the grains, achieving an optimal storage humidity.

sorghum dryer Introduction

Advantages of sorghum dryer

Professional design

The dryer is specifically developed for premium small packaging, capable of generating maximum profit.

Uniform drying

Equipped with a forced dispersion device and multiple rotary valves for quantitative feeding circulation, ensuring even drying of sorghum seeds.

Durable materials

Utilizes long-lasting materials such as a large spiral feeder, large plastic steel buckets, and stainless steel mesh plates.

High efficiency

Features a high-efficiency exhaust fan and fully open drying layers, resulting in fast drying speeds and high efficiency.

Eco-friendly heat source

Options include oil or a combustion furnace as the heat source. The combustion furnace can use coal, rice husks, wood, or other biomass waste materials as fuel, ensuring no pollution to the sorghum. This makes it an excellent and low-cost eco-friendly device.

Wide applicability

In addition to sorghum, it is also suitable for drying rice, wheat, mung beans, soybeans, and other grains.

Energy-saving design

Implements a recirculating drying design to save energy and includes automatic temperature and moisture detection controls to prevent over-drying, ensuring the quality of the grains.

Low-temperature drying

The 5HY sorghum dryer employs a low-temperature drying method to ensure drying quality.

Self-circulating system

Certain models feature a self-circulating system capable of rapid drying, cleaning, cooling, and other functions.

Main Components of sorghum dryer

Hot Air Furnace

Generates hot air as the heat source for the dryer. It can use various energy sources, including gas, oil, electricity, and biomass fuel.

Drying Chamber

Where sorghum is dried by hot air. The design of the drying chamber can vary, such as drum type, tower type, or flat type.

Conveying System

Includes feeding and discharging devices to transport sorghum into and out of the drying chamber. Common conveying equipment includes belt conveyors and screw conveyors.

Ventilation System

Comprises fans and ducts to distribute hot air evenly throughout the drying chamber and to expel moisture.

Control System

Regulates and controls temperature, humidity, and airspeed during the drying process, ensuring optimal drying results. Modern control systems are usually automated for precise control.

Working Principle of sorghum dryer

Feeding

Sorghum is fed into the drying chamber via the conveying system.

Heating and Ventilation

The hot air furnace generates hot air, which enters the drying chamber through the ventilation system, contacting the sorghum and causing moisture to evaporate.

Drying Process

Sorghum is evenly distributed within the drying chamber, and the hot air removes moisture from the sorghum's surface. The sorghum is continuously agitated or moved to ensure uniform heating.

Moisture Removal

The evaporated moisture is expelled from the drying chamber via the ventilation system, maintaining a dry environment inside the chamber.

Discharging

Sorghum, now dried to the desired moisture content, is discharged from the drying chamber through the conveying system, completing the drying process.

Advantages of sorghum dryer

High Efficiency and Energy Saving

Modern sorghum dryers typically use efficient heat sources and advanced hot air circulation systems, enhancing drying efficiency and reducing energy consumption.

High Degree of Automation

The automatic control system precisely adjusts drying parameters, reducing manual intervention and improving drying quality.

Uniform Drying

Well-designed drying chambers and ventilation systems ensure that sorghum is evenly heated during the drying process, preventing localized overheating or under-drying.

Strong Adaptability

Capable of handling different varieties, initial moisture levels, and production capacities of sorghum, offering broad applicability.

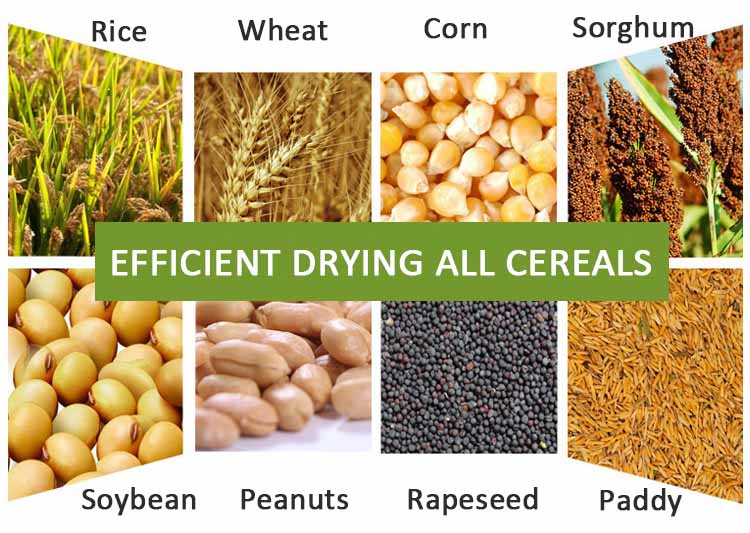

sorghum dryer Application

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

sorghum dryer Machine Technical Parameter

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.