Seed dryer

Seed dryer are agricultural machinery designed to reduce the moisture content of seeds. Seeds usually contain high moisture after harvest. If they are not properly dried, they are prone to mold and deterioration, affecting the storage life and germination ability of seeds.

Seed dryer Introduction

Seed dryer are agricultural machinery designed to reduce the moisture content of seeds. Seeds usually contain high moisture after harvest. If they are not properly dried, they are prone to mold and deterioration, affecting the storage life and germination ability of seeds. Seed dryer control drying conditions, remove excess moisture, and help seeds reach a safe moisture level suitable for storage and sowing.

Features of seed dryer

Gentle Drying

We use a gentle drying method to avoid high temperatures that could damage the seed embryo and vitality.

Uniform Drying

We ensure even heating during the drying process to prevent uneven drying.

Precise Control

We equip the machines with precise temperature and humidity control systems to accommodate the drying needs of different seeds.

Energy Efficiency and Environmental Protection

We focus on energy efficiency in our designs, incorporating energy-saving technologies and clean energy sources.

Automated Operation

We implement automated control to reduce manual intervention and increase work efficiency.

Adaptability

Our machines are adaptable to different types of seeds, including grains, vegetables, and flowers.

Easy Maintenance

We design the machines to be simple for routine maintenance and cleaning.

Operational Safety

We include necessary safety features to ensure the safety of operators.

Hygiene and Cleanliness

We ensure the drying process meets hygiene standards to prevent contamination of seeds.

Durability

We construct the machines using durable materials to guarantee long-term stable operation.

Structure of seed dryer

Gentle Drying

We use a gentle drying method to avoid high temperatures that could damage the seed embryo and vitality.

Uniform Drying

We ensure even heating during the drying process to prevent uneven drying.

Precise Control

We equip the machines with precise temperature and humidity control systems to accommodate the drying needs of different seeds.

Energy Efficiency and Environmental Protection

We focus on energy efficiency in our designs, incorporating energy-saving technologies and clean energy sources.

Automated Operation

We implement automated control to reduce manual intervention and increase work efficiency.

Adaptability

Our machines are adaptable to different types of seeds, including grains, vegetables, and flowers.

Easy Maintenance

We design the machines to be simple for routine maintenance and cleaning.

Operational Safety

We include necessary safety features to ensure the safety of operators.

Hygiene and Cleanliness

We ensure the drying process meets hygiene standards to prevent contamination of seeds.

Durability

We construct the machines using durable materials to guarantee long-term stable operation.

Advantages of seed dryer

Improved Seed Quality

By reducing the moisture content to optimal levels, we help maintain the viability and germination rate of seeds.

Efficient Drying

We engineer the machines for high-efficiency drying, which shortens the drying time and increases throughput.

Uniformity

We ensure uniform drying of seeds, which is crucial for consistent seed performance post-storage.

Controlled Environment

We provide precise control over temperature and humidity, which is essential for the delicate drying process of seeds.

Energy Saving

We incorporate energy-efficient technologies to minimize power consumption and reduce operational costs.

Versatility

Our machines are versatile, capable of drying a wide range of seed types and sizes.

Automation

We offer automated operation, which reduces the need for constant supervision and manual labor.

Safety

We prioritize safety with features such as automatic shut-offs and temperature control to prevent damage to seeds.

Ease of Maintenance

We design the machines for ease of maintenance, ensuring that they remain in optimal working condition.

Durability

We construct the machines using high-quality materials to ensure they are robust and long-lasting.

Hygiene

We ensure the drying process is hygienic, preventing contamination and preserving the integrity of the seeds.

Scalability

Our machines can be scaled to meet the needs of different production capacities, from small-scale to large commercial operations.

Environmental Consideration

We design the machines with environmental impact in mind, aiming to reduce the carbon footprint and promote sustainability.

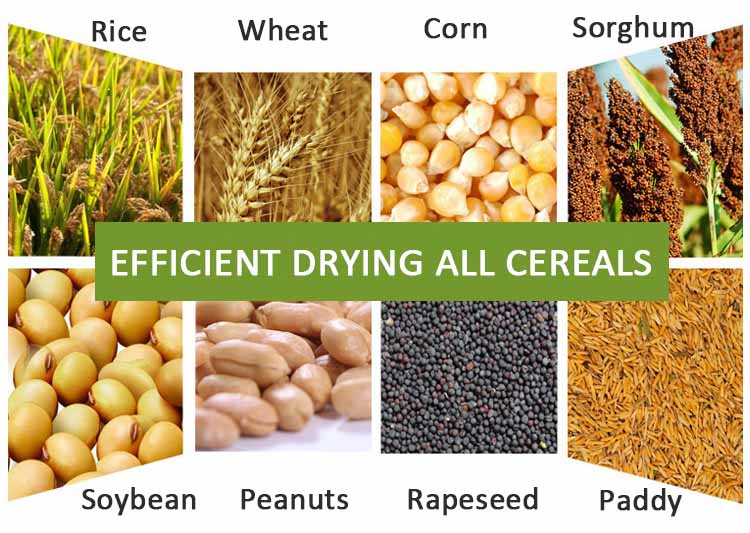

Seed dryer Application

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

Seed dryer Technical Parameter

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.