rice dryer

A rice dryer is a specialized equipment used to evaporate moisture from rice, thereby improving its quality and extending its shelf life. It typically employs hot air or other heating methods to subject rice to appropriate temperature and humidity conditions, continuously drying it to the desired level of dryness.

rice dryer Introduction

A rice dryer is a specialized equipment used to evaporate moisture from rice, thereby improving its quality and extending its shelf life. It typically employs hot air or other heating methods to subject rice to appropriate temperature and humidity conditions, continuously drying it to the desired level of dryness. Rice dryers play a crucial role in rice processing and production, effectively preventing rice from molding, dampening, and deteriorating in quality, while also extending its storage period.

Features of rice dryer

Versatility

Rice dryers are designed to accommodate various types of rice, including long-grain, medium-grain, and short-grain rice, as well as specialty rice varieties.

Efficiency

Rice dryers employ advanced drying technology and equipment to efficiently remove moisture from rice grains, ensuring thorough and uniform drying.

Precise control

Many rice dryers are equipped with sophisticated temperature and humidity control systems, allowing operators to adjust drying conditions according to specific rice varieties and desired moisture levels.

Gentle handling

To preserve the integrity of rice grains and minimize breakage, rice dryers are designed to handle grains gently during the drying process, often incorporating features such as gentle conveying mechanisms and adjustable airflow patterns.

Energy efficiency

Modern rice dryers are engineered to maximize energy efficiency, employing features such as insulated drying chambers, heat recovery systems, and variable-speed fans to minimize energy consumption and operating costs.

Safety

Rice dryers are equipped with safety features such as temperature sensors, flame detectors, and emergency shut-off mechanisms to ensure safe operation and prevent accidents.

Ease of maintenance

Rice dryers are designed for easy maintenance, with accessible components and removable parts that facilitate routine inspections, cleaning, and repairs.

The structure of rice dryer

Drying chamber

This is the primary area where rice grains are subjected to heat to remove moisture. It typically contains heating elements or burners to generate heat.

Conveyor system

Rice dryers are equipped with conveyor systems to transport rice grains through the drying chamber. This can be in the form of belts, augers, or other mechanisms.

Heat source

A heat source is required to generate the necessary heat for drying rice. This can be provided by gas burners, electric heaters, or other heating elements.

Air circulation system

An air circulation system is essential for distributing heat evenly throughout the drying chamber. Fans or blowers are used to circulate hot air, ensuring uniform drying.

Control panel

Rice dryers feature control panels where operators can set and monitor parameters such as temperature, humidity, and drying time. This allows for precise control of the drying process.

Exhaust system

Rice dryers are equipped with exhaust systems to remove moisture-laden air from the drying chamber. This helps maintain the desired drying conditions and prevents overheating.

Insulation

Insulation is important for retaining heat within the drying chamber and improving energy efficiency. It helps reduce heat loss to the surroundings, ensuring effective drying.

Safety features

Rice dryers may include safety features such as temperature sensors, flame detectors, and emergency shut-off mechanisms to prevent accidents and ensure safe operation.

Advantages of rice dryer

Improved quality

By effectively removing excess moisture from rice grains, rice dryers enhance the quality of the rice by preventing mold growth, reducing the risk of spoilage, and preserving its natural flavor and texture.

Extended shelf life

Properly dried rice has a longer shelf life as it is less prone to spoilage and deterioration. This helps reduce food wastage and ensures a consistent supply of high-quality rice for consumers.

Increased efficiency

Rice dryers allow for large quantities of rice to be dried efficiently and uniformly, reducing the overall processing time and increasing productivity in rice mills and processing plants.

Customization options

Many rice dryers offer customizable drying parameters such as temperature, humidity, and drying time, allowing operators to tailor the drying process to suit different types of rice and specific quality requirements.

Energy efficiency

Modern rice dryers are designed to be energy-efficient, with features such as insulated drying chambers, heat recovery systems, and adjustable airflow patterns that help minimize energy consumption and operating costs.

Reduced labor requirements

Automated controls and continuous operation modes reduce the need for manual intervention, leading to lower labor costs and increased operational efficiency.

Safety features

Rice dryers are equipped with safety mechanisms such as temperature sensors, flame detectors, and emergency shut-off systems to prevent accidents and ensure safe operation in rice processing facilities.

Environmental benefits

Properly dried rice reduces the risk of mold contamination and spoilage, resulting in less food waste and lower environmental impact. Additionally, energy-efficient rice dryers help reduce greenhouse gas emissions and conserve natural resources.

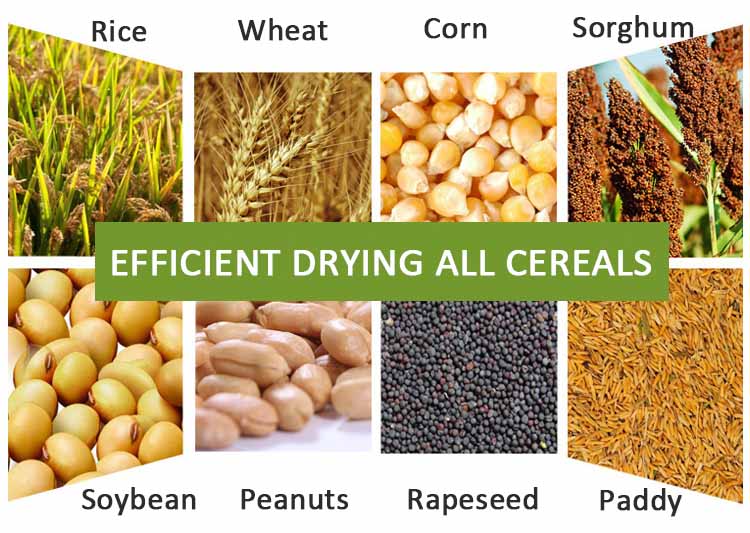

Rice dryer Application

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

Rice dryer Machine Technical Parameter

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.