Corn grain dryer

Corn grain dryer is a kind of equipment specially used for drying and processing grains such as corn, wheat, and rice. It is suitable for users such as farms, grain stations, and grain growers. This equipment can realize multiple uses of one machine, save drying costs, improve drying efficiency, ensure grain quality, and extend grain storage time.

Corn grain dryer Introduction

Corn grain dryer is a kind of equipment specially used for drying and processing grains such as corn, wheat, and rice. It is suitable for users such as farms, grain stations, and grain growers. This equipment can realize multiple uses of one machine, save drying costs, improve drying efficiency, ensure grain quality, and extend grain storage time. The selection of corn grain dryer is based on the actual local conditions and the comprehensive analysis of the requirements of two important indicators, the productivity of the dryer and the precipitation range.

Depending on the scale of agricultural production and the amount of grain drying, users can choose small or large dryers of different capacities. Small grain dryers are usually used to process rush-harvest grain crops such as wheat, corn, rice, and beans, while large dryers are suitable for concentrated grain production areas to process large quantities of grain during the drying season.

Functional features of corn grain dryer

Rapid Drying

The corn dryer quickly removes excess moisture from harvested corn, significantly speeding up the drying process compared to traditional sun-drying methods, thereby improving drying efficiency.

Even Drying

With an advanced hot air circulation system and homogenizer, the corn dryer ensures uniform heating during the drying process, resulting in consistent drying outcomes.

Prevention of Mold and Decay

By swiftly removing excess moisture from the corn, the dryer effectively prevents mold, spoilage, and sprouting caused by high moisture levels, ensuring the quality and safety of stored corn.

Enhanced Storage Stability

Dried corn is less susceptible to microbial and pest attacks during storage, preserving its nutritional value and quality. Additionally, the physical and chemical properties of dried corn are more stable, reducing quality fluctuations caused by moisture changes.

Increased Market Supply

The corn dryer allows for timely drying and market availability of corn, regardless of adverse weather conditions like continuous rain, helping to stabilize market supply and meet demand across different periods.

Improved Economic Benefits

By reducing economic losses due to quality deterioration and increasing sales prices and competitiveness, the corn dryer provides tangible economic benefits to farmers.

Long-Term Storage

The dryer creates favorable conditions for the long-term storage of corn, allowing it to be preserved for extended periods, meeting future production and consumption needs.

Preservation of Nutritional Content and Taste

Dried corn retains its original shape and color, with no loss of nutritional content or flavor. The drying process also provides a sterilizing effect, making the corn healthier and more hygienic.

Resource Conservation

The corn dryer utilizes advanced energy-saving technologies, such as heat recovery devices and intelligent control systems, which automatically adjust according to seasonal and corn variety characteristics, reducing energy waste and conserving resources.

Ease of Operation

The corn dryer is easy to install and operate, requiring minimal auxiliary equipment, making it convenient for transportation and movement. It is well-suited for farms, grain stations, and professional grain growers.

Corn grain dryer structure

Heating System

The heating system is the core component of the dryer, responsible for generating and transmitting heat. It may use fuel combustion (such as coal, biomass, etc.) or electricity to heat water or air, providing the necessary thermal energy for drying.

Ventilation System

The ventilation system delivers heated air to the corn and expels the moisture-laden air. This ensures proper airflow within the dryer, optimizing the drying process.

Conveying System

The conveying system transports corn from the inlet to the outlet of the dryer. During this process, the corn passes through heating and ventilation zones, gradually achieving the desired level of dryness. This system typically includes feeding mechanisms, conveyor belts, or screw conveyors.

Control System

Serving as the brain of the entire drying equipment, the control system monitors and regulates parameters such as temperature, humidity, feed rate, and fuel consumption throughout the drying process. Precise control ensures stability and efficiency during operation.

Combustion Equipment (if applicable)

For dryers using combustion as the heat source, combustion equipment is essential. This typically includes a fuel storage tank, burners, and combustion fans, all of which work together to provide a steady heat source for the dryer.

Dehumidification Equipment

To enhance drying efficiency, some dryers are equipped with dehumidification devices. These units remove moisture generated during the drying process, further accelerating drying.

Additional Auxiliary Equipment

Depending on specific drying needs and production scale, corn dryers may also include auxiliary equipment such as storage silos, cleaning machines, and coolers. These components contribute to improved drying outcomes and overall production efficiency.

Key Advantages of Corn Grain Dryer

Energy Efficiency

The dryer utilizes advanced drying technology and a high-efficiency heating system, enabling the rapid drying of large quantities of corn while minimizing energy consumption and reducing production costs.

Uniform Drying

By precisely controlling parameters such as temperature, humidity, and airflow speed, the dryer ensures that the corn is evenly heated during the drying process, preventing issues like overheating or under-drying, and thus maintaining high drying quality.

High Automation

Modern corn dryers are typically equipped with intelligent control systems that automatically monitor and adjust various parameters throughout the drying process. This reduces the need for manual intervention, enhancing both production efficiency and stability.

Eco-friendly and Hygienic

The dryer often uses clean energy sources, such as electricity or biomass, during the drying process, which reduces environmental pollution. Additionally, the dried corn is more hygienic, contributing to improved food safety.

Loss Reduction

The dryer quickly removes excess moisture from the corn, preventing issues like mold, rot, and sprouting, thereby reducing economic losses. Moreover, the dried corn is easier to store and transport, further minimizing losses during these processes.

Quality Improvement

The dryer preserves the original nutritional content and taste of the corn and may even have sterilization functions, resulting in higher-quality corn that is more attractive to the market.

Adaptability

The dryer can be adjusted and optimized according to different corn varieties and drying requirements, offering strong adaptability and flexibility.

Economic Benefits

By improving drying efficiency and quality, the dryer increases farmers' income and boosts economic returns. Additionally, it mitigates delays and losses caused by weather and other factors, further stabilizing market supply and prices.

Application of Corn grain dryer

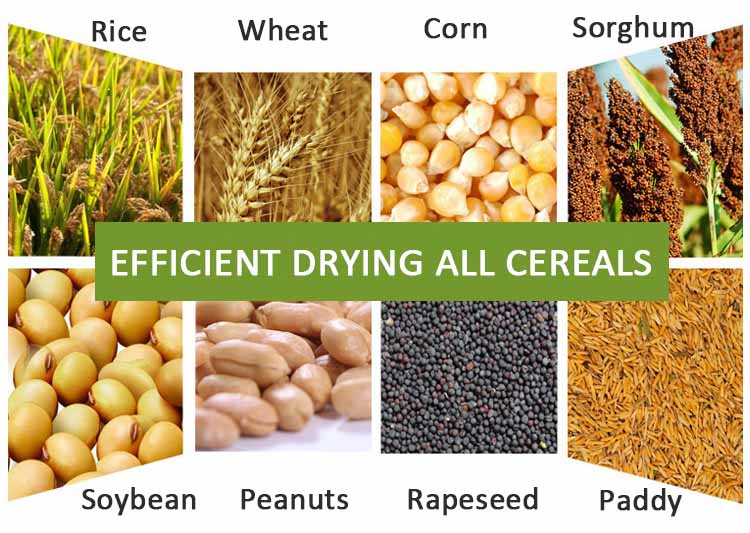

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

Technical parameters of Corn grain dryer

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.