corn dryer

A corn dryer is a device used to remove moisture from freshly harvested corn. Similar to wheat dryers, corn dryers expose moist corn

corn dryer Introduction

A corn dryer is a device used to remove moisture from freshly harvested corn. Similar to wheat dryers, corn dryers expose moist corn to hot air or other heating methods to accelerate the evaporation of moisture. This helps maintain the quality of the corn, preventing the growth of mold and other microorganisms, while also extending its shelf life. Corn dryers come in various types and sizes, ranging from small household equipment to large industrial-grade machinery. These devices play a crucial role in agricultural production, especially in situations requiring the storage and transportation of large quantities of corn.

Characteristics of corn dryer

Rapid drying

Corn dryers can quickly remove moisture from corn, effectively preventing the growth of mold and other microorganisms, thereby helping to maintain the quality of the corn.

Automated control

Many corn dryers are equipped with automated control systems that can monitor and adjust temperature, humidity, and ventilation speed during the drying process to ensure optimal drying results.

High energy efficiency

Modern corn dryers are typically designed for high energy efficiency, meaning they can quickly dry corn while minimizing energy consumption and reducing production costs.

Versatility

Some corn dryers are multifunctional, able to adapt to the drying needs of different types and scales of corn, and can also be used for drying other grains.

Durability and reliability

High-quality corn dryers exhibit good durability and reliability, capable of long-term stable operation, thus reducing maintenance and repair costs.

Environmental friendliness

Some modern corn dryers are designed with environmental considerations in mind, employing advanced emission control technologies to minimize environmental impact and comply with environmental regulations.

Structure of corn dryer

Drying chamber/Cylinder

This is the space where corn or other grains are placed for drying. The drying chamber is typically a sealed metal container with appropriate design inside to ensure even heat distribution and efficient drying of the grains.

Fan/Blower

A fan or blower is used to generate airflow and deliver hot air into the drying chamber. This helps accelerate the evaporation of moisture and ensures uniformity in the drying process.

Heater

The heater is responsible for heating the air entering the drying chamber. Common types of heaters include electric heaters, gas heaters, or steam heaters, aiming to provide sufficient heat to facilitate moisture evaporation.

Control system

The control system is used to monitor and regulate parameters such as temperature, humidity, and airflow speed during the drying process. Modern corn dryers are typically equipped with advanced automation control systems to ensure stability and efficiency in the drying process.

Conveying system

The conveying system is used to transport corn or other grains from the inlet to the drying chamber and, after drying, to convey them out from the outlet. These systems typically include conveyor belts, screw conveyors, or other types of conveying devices.

Dust removal system

The dust removal system serves to eliminate dust and impurities produced during drying. This helps maintain cleanliness within the drying chamber and prevents dust from affecting equipment and corn quality.

Advantages of corn dryer

Efficient Drying

Corn dryers can rapidly remove moisture from corn, reducing drying time and preserving its quality.

Customized Drying

Many corn dryers are equipped with adjustable settings. These settings enable users to customize drying parameters such as temperature and airflow to suit different types of corn and environmental conditions.

Energy Efficiency

Modern corn dryers are designed to minimize energy consumption while effectively drying corn, reducing operational costs.

Preservation of Quality

Corn dryers efficiently remove moisture, preventing mold growth and preserving the nutritional value and quality of the corn.

Versatility

Corn dryers are versatile and adaptable to different agricultural settings, suitable for drying various grains besides corn.

Increased Productivity

Corn dryers enable farmers to process larger quantities of corn efficiently. This is achieved through faster drying times and customizable settings, ultimately increasing overall productivity.

Reduced Spoilage

Promptly drying corn after harvest reduces the risk of spoilage and ensures that the crop remains marketable for longer periods.

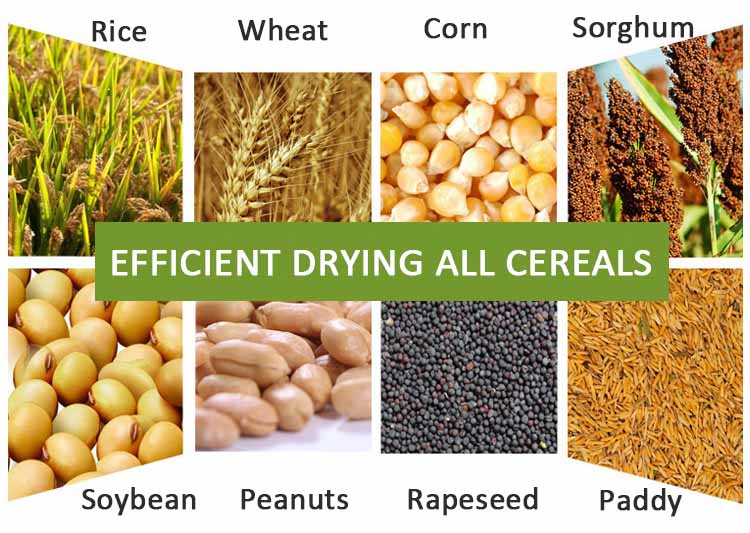

corn dryer Application

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

Technical parameters of corn dryer

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.