Commercial Grain Dryer

Commercial grain dryer are specialized equipment designed for the drying of grains. They can efficiently remove moisture from freshly harvested grains to ensure that the grains reach a safe moisture level before storage, thus preventing losses due to mold, germination, and pests.

Commercial Grain Dryer Introduction

Commercial grain dryer are specialized equipment designed for the drying of grains. They can efficiently remove moisture from freshly harvested grains to ensure that the grains reach a safe moisture level before storage, thus preventing losses due to mold, germination, and pests. These machines are widely used in the agricultural sector, especially after the harvest of grains, where it is necessary to quickly reduce the moisture content of the grains for storage and transportation.

Features of Commercial Grain Dryer

Large Capacity

Commercial grain dryers typically have a high processing capacity, allowing them to handle large quantities of grain in a short period, making them suitable for large farms and grain processing enterprises.

Automated Control

Many commercial grain dryers are equipped with advanced automated control systems. These systems can automatically adjust drying parameters based on the type and moisture content of the grain, ensuring precise and efficient drying.

Efficient Energy Use

Modern commercial grain dryers are designed for efficient energy use, reducing energy consumption and lowering operating costs. Common heat sources include natural gas, diesel, electricity, and biomass fuels.

Circulation System

Some dryers are equipped with air circulation systems that dry the grains more evenly while saving energy.

Various Types

There are several types of commercial grain dryers, including continuous dryers, batch dryers, tower dryers, and rotary drum dryers. This variety allows for selecting the type that best meets specific needs.

Easy Maintenance

These dryers are designed with ease of maintenance and cleaning in mind, reducing downtime and increasing production efficiency.

Structure of Commercial Grain Dryer

Elevator System

It lifts the grain from the hopper to the main body of the dryer. This usually includes an elevator and conveyor belts.

Drying Chamber/Tower

This is the core part of the dryer where the grain is dried. The drying chamber can be designed horizontally or vertically, depending on the type of dryer.

Heat Source System

Provides the thermal energy required for drying. The heat source can be biomass, coal, natural gas, electricity, etc.

Hot Air Furnace/Heat Exchanger

Used to heat the air to generate hot air, which then passes through the grain layer for heat and moisture exchange.

Circulation System

Includes fans and blowers that control the flow and circulation of hot air within the drying chamber.

Automatic Control System

Typically uses PLC control, including a touch screen interface, which can automatically adjust the drying temperature and time, monitor the drying process, and stop automatically when the set moisture content is reached.

Material Conveying System

Transports the grain from the elevator system to the drying chamber and to the unloading area after drying.

Unloading System

Used to unload the dried grain from the dryer, which can be a screw conveyor, belt conveyor, or other types of conveying equipment.

Dust Removal and Moisture Exhaust System

Used to remove moisture and dust generated during the drying process, maintaining a clean working environment.

Advantages of Commercial Grain Dryer

Improved Drying Efficiency

Commercial grain dryers can rapidly reduce the moisture content of grains, shorten the drying time, and enhance production efficiency.

Quality Assurance

By precisely controlling the drying conditions, such as temperature and humidity, they ensure even drying of grains, preventing over-drying or under-drying, thus maintaining the quality of the grains.

Automated Operation

Equipped with advanced automatic control systems, they reduce manual intervention and increase the convenience and reliability of operations.

Energy Saving and Environmental Protection

Many commercial grain dryers are designed with energy-saving features, using heat exchange technology to reduce energy consumption and minimize environmental impact.

Reduced Losses

They effectively prevent mold, germination, and pest infestation due to high humidity, reducing losses during storage and transportation.

Strong Adaptability

Commercial grain dryers are typically available in various models and specifications to meet the drying needs of different types and scales of grains.

Easy Maintenance

Reasonably designed structures facilitate routine inspections and maintenance, reducing long-term operating costs.

Enhanced Storage Safety

By reducing the moisture content of grains, they improve storage safety and extend the storage time.

High Flexibility

Especially mobile grain dryers can be used in different locations as needed, adding to their flexibility of use.

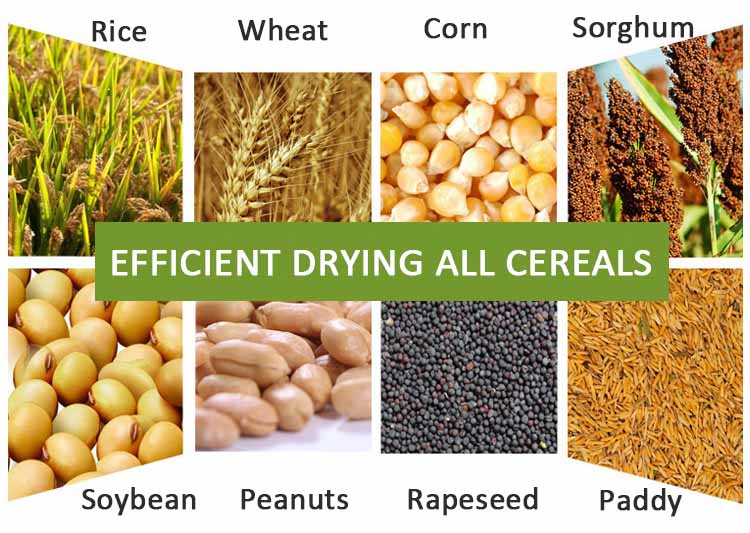

Commercial Grain Dryer Application

The Grain dryer machine is suitable for efficiently drying all cereals,grains,beans,and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

Commercial Grain Dryer Technical Parameter

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.