circulating grain dryer

A circulating grain dryer is a type of equipment used for drying grains by repeatedly processing them to reduce their moisture content. This dryer uses a circulation system to continuously pass hot air through the grain layers

circulating grain dryer Introduction

A circulating grain dryer is a type of equipment used for drying grains by repeatedly processing them to reduce their moisture content. This dryer uses a circulation system to continuously pass hot air through the grain layers, enabling the evaporation of moisture and ensuring uniform drying of the grains. This process prevents over-drying or under-drying in specific areas.

Features of Circulating Grain Dryer

Multiple Drying Cycles

During the drying process, grains pass through the dryer multiple times, with each cycle further reducing their moisture content. This approach ensures that the grains achieve uniform drying throughout the entire batch.

Automated Control System

circulating grain dryer are typically equipped with automated control systems that adjust drying parameters based on the initial and target moisture content of the grains, ensuring precise and efficient drying.

Energy-Efficient Design

Modern recirculating grain dryers feature energy-efficient designs, utilizing heat exchange technology and hot air recirculation systems to maximize energy utilization efficiency and reduce energy consumption and operating costs.

High-Efficiency Energy Utilization

The hot air recirculation system can recover and reuse heat, enhancing drying efficiency while minimizing heat loss.

Multi-Purpose

This type of dryer can handle various grains, including wheat, corn, rice, and barley, making it suitable for different types of agricultural products drying needs.

High Processing Capacity

Recirculating grain dryers typically have a high processing capacity, allowing them to handle large quantities of grains in a short period, making them suitable for large farms and grain processing enterprises.

Easy Maintenance

The design considers the convenience of daily maintenance and cleaning, reducing downtime and increasing production efficiency.

Uniform Drying

Due to the multiple cycles that grains go through during the drying process, each grain can be uniformly heated, achieving ideal drying results.

Structure of circulating grain dryer

Feeding System

This system is used to transport the grains to be dried into the dryer. It typically includes a feed hopper, conveyor belt, or screw conveyor.

Drying Chamber

This is the main part where the grains are dried. It contains multiple drying layers or drying towers where the grains are dried through the hot air circulation system.

Hot Air Generator

Responsible for producing hot air used to dry the grains. The hot air generator can use different fuels such as natural gas, diesel, electricity, or biomass fuels.

Circulation Fan

Used to circulate the hot air through the grain layers, ensuring even distribution of hot air and achieving uniform drying.

Moisture Exhaust System

Used to expel the moist air generated during the drying process, maintaining appropriate humidity within the drying chamber.

Control System

Includes temperature sensors, humidity sensors, and an automated control panel to monitor and adjust various parameters during the drying process, ensuring optimal drying results.

Discharging System

Used to transport the dried grains out of the dryer, typically including a discharge port, conveyor belt, or screw conveyor.

Frame Structure

Provides support and protection for all components of the dryer, usually made of durable metal materials.

Heat Exchanger

Used to recover and reuse the heat from the hot air, improving energy efficiency and reducing energy consumption.

Safety System

Includes fire prevention equipment, high-temperature alarm devices, etc., to ensure safety during the drying process.

Advantages of circulating grain dryer

Uniform Drying

The circulation system ensures that hot air is evenly distributed throughout the grain layers, ensuring every part of the grain is adequately dried and preventing over-drying or under-drying in specific areas.

High Energy Efficiency

Recirculating grain dryers are typically equipped with heat exchangers and circulation fans that recover and reuse heat from the hot air, significantly improving energy efficiency and reducing energy consumption and operating costs.

High Processing Capacity

These machines are usually designed with large capacity, allowing them to process large quantities of grain in a short period, making them suitable for large farms and grain processing enterprises.

Automated Control

Modern recirculating grain dryers feature advanced automated control systems that can monitor and adjust parameters such as temperature and humidity in real-time, ensuring precise and efficient drying.

Versatility

They are suitable for drying various grains, including wheat, corn, rice, barley, etc., meeting the drying needs of different agricultural products.

Energy Saving and Environmentally Friendly

With efficient heat recovery systems and optimized combustion technology, these dryers reduce environmental impact while lowering operating costs.

Easy Maintenance

The design considers the convenience of daily maintenance and cleaning, reducing downtime and increasing production efficiency.

Improved Grain Quality

By precisely controlling the drying process, recirculating grain dryers effectively reduce grain loss and improve the quality and market value of the grain.

Reliability and Durability

Made with high-quality materials and advanced manufacturing techniques, recirculating grain dryers typically have a long service life and high reliability.

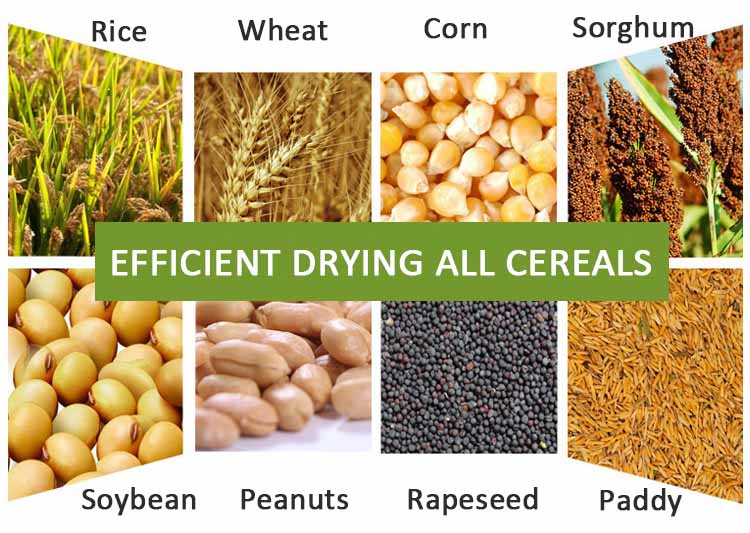

Grain Dryer Application

The Grain dryer machine is suitable for efficiently drying all cereals,grains,beans,and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

Grain dryer Machine Technical Parameter

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.