bean dryer

Bean dryer is a kind of agricultural machinery specially designed to reduce the moisture content of bean crops. Since beans contain high moisture after harvest, they need to be dried to reduce the moisture content, thereby extending the storage life, preventing mold and rot, and maintaining the quality and nutritional value of beans.

bean dryer Introduction

Bean dryer is a kind of agricultural machinery specially designed to reduce the moisture content of bean crops. Since beans contain high moisture after harvest, they need to be dried to reduce the moisture content, thereby extending the storage life, preventing mold and rot, and maintaining the quality and nutritional value of beans.

Features of bean dryer

Gentle Drying

We employ gentle drying techniques to prevent high temperatures from damaging the nutritional components and seed viability of the beans.

Uniform Heating

We ensure even heat distribution throughout the drying process to achieve uniform drying.

Precise Control

We equip the machines with precise temperature and humidity control systems to cater to the needs of different types of beans and various drying stages.

Energy Efficiency and Environmental Protection

We incorporate energy-saving designs and clean energy sources to minimize energy consumption and environmental impact.

Automated Operation

We implement automated control to reduce manual intervention and increase production efficiency.

Adaptability

Our machines are adaptable to various kinds of beans, such as soybeans, red beans, green beans, etc.

Ease of Maintenance

We design the machines to be straightforward for routine maintenance and cleaning.

Operational Safety

We integrate necessary safety features to ensure the safety of operators.

Hygiene and Cleanliness

We guarantee that the drying process meets hygiene standards to prevent contamination of the beans.

Durability

We construct the machines using durable materials to ensure long-term stable operation.

The structure of bean dryer

Feeding System

We design a feeding system to deliver beans into the drying chamber uniformly, often consisting of conveyor belts or vibratory feeders.

Drying Chamber

We create the drying chamber as the central component where beans are exposed to a controlled drying environment.

Heat Source

We integrate a heat source to generate the necessary heat for the drying process, which can include electric heaters, gas burners, or other thermal systems.

Air Circulation System

We engineer an air circulation system to distribute hot air evenly throughout the drying chamber, ensuring consistent bean drying.

Moisture Removal System

We incorporate a system to remove excess moisture, typically involving exhaust fans and vents to expel humid air.

Discharge System

We design a discharge system for the removal of dried beans from the machine, often using conveyors or discharge screws.

Control Panel

We include a control panel with sensors and controls to monitor and adjust the drying parameters, such as temperature, humidity, and airflow.

Thermal Insulation

We apply thermal insulation to the drying chamber to retain heat and improve energy efficiency.

Safety Features

We integrate safety features like emergency shut-offs and temperature alarms to protect both the operator and the equipment.

Cleaning System

We may include a cleaning system for the easy removal of dust and debris, ensuring the hygiene of the drying process.

Structural Frame

We build a robust structural frame to support the machine components and provide stability during operation.

Filter System

We sometimes incorporate a filter system to clean the air entering the drying chamber, preventing contamination of the beans.

Advantages of bean dryer

Efficient Drying

The machines are engineered to dry beans quickly, which increases throughput and reduces drying time.

Uniformity

They ensure that all beans are dried evenly, which is important for maintaining the quality and consistency of the final product.

Controlled Conditions

We provide precise control over the drying conditions, including temperature and humidity, to suit the specific needs of various bean types.

Energy Efficiency

The machines are designed to be energy efficient, minimizing energy consumption and reducing operational costs.

Versatility

They are capable of drying a wide variety of beans, offering flexibility in processing different types of legume crops.

Automation

We incorporate automation features that reduce the need for manual labor and allow for unattended operation during the drying cycle.

Safety

We prioritize safety with built-in features such as emergency stop buttons and over-temperature protection to prevent accidents.

Ease of Maintenance

The machines are designed for easy maintenance, ensuring that they remain in good working order with minimal downtime.

Hygiene

We ensure the drying process is conducted under hygienic conditions to prevent contamination and preserve bean quality.

Durability

High-quality materials are used in construction to ensure the machine is durable and can withstand the rigors of continuous use.

Scalability

The machines can be scaled to meet different production capacities, making them suitable for both small and large-scale operations.

Environmental Consideration

We design the machines with an eye toward environmental sustainability, aiming to reduce their ecological footprint.

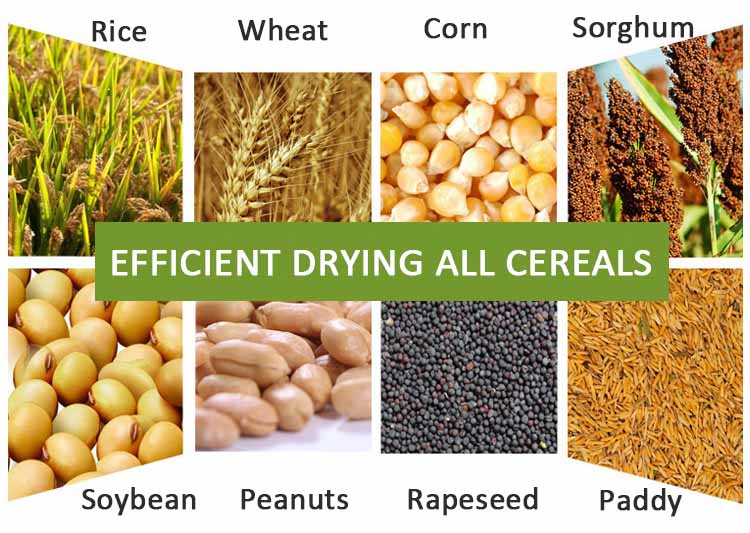

bean dryer Application

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat,Lentils,Sesame,rice, soybean, sorghum,Sunflower seeds,Coffee Beans,rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

bean dryer Technical Parameter

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | ||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.