Barley dryer

Barley dryer is a kind of agricultural machinery specially designed to remove excess water from barley. Barley usually contains high water content after harvest, and needs to be reduced through the drying process to facilitate storage, transportation and processing.

Barley dryer Introduction

Barley dryer is a kind of agricultural machinery specially designed to remove excess water from barley. Barley usually contains high water content after harvest, and needs to be reduced through the drying process to facilitate storage, transportation and processing. Barley dryer heats the air or other media to transfer heat to the barley, accelerate the evaporation of water, and thus achieve the purpose of drying.

Features of barley dryer

Efficient Drying

They are capable of rapidly reducing the moisture content of barley in a short amount of time.

Uniform Heating

We ensure even heat distribution throughout the drying process to prevent local overheating or uneven drying.

Temperature Control

Equipped with an accurate temperature control system to accommodate different varieties and moisture contents of barley.

Energy Saving and Environmental Protection

Incorporating energy-saving technologies and clean energy sources to reduce energy consumption and environmental pollution.

Automated Operation

Featuring an automated control system that simplifies the operational process and increases production efficiency.

Adaptability

Designed to adapt to barley of different varieties, maturities, and initial moisture contents.

Easy Maintenance

The design takes into account the convenience of maintenance for easy routine inspections and upkeep.

Cleanliness and Hygiene

We ensure the drying process meets food safety and hygiene standards.

Safety Protection

Equipped with multiple safety features to ensure the safety of operators.

Durability

Constructed with high-quality materials and superior manufacturing processes to ensure the durability and long-term stable operation of the equipment.

The structure of barley dryer

Feeding System

We integrate a feeding system to uniformly convey barley into the drying chamber, often including conveyor belts and vibratory feeders.

Drying Chamber

We construct the drying chamber as the core part of the barley drying machine, where the barley is housed for the drying process.

Heat Exchange System

We incorporate a heat exchange system to provide thermal energy, heating the air or other drying media to facilitate the evaporation of moisture from the barley.

Circulation System

We design a circulation system with fans and ducts to circulate hot air or drying media, ensuring uniform temperature and humidity throughout the drying chamber.

Moisture Removal System

We implement a system to remove moisture, using exhaust fans and ducts to expel the humidity released from the barley, maintaining a dry environment within the chamber.

Discharge System

We develop a discharge system to remove the dried barley from the drying machine, typically consisting of discharge screws and conveyor belts.

Control System

We include a control system with various sensors, controllers, and interfaces to monitor and adjust parameters such as temperature, humidity, and airflow during the drying process.

Support Structure

We engineer a support structure with frameworks and supports to provide a stable foundation for the drying machine.

Cleaning and Maintenance System

We may include cleaning equipment and tools to facilitate regular cleaning and maintenance of the machine.

Safety System

We incorporate safety systems with emergency stop buttons, overload protection, and high-temperature alarms to ensure operational safety.

Advantages of barley dryer

Efficiency

Barley drying machines are engineered to dry large quantities of barley quickly, improving operational efficiency.

Uniformity

They ensure even drying of the barley, which is critical for maintaining product quality and avoiding uneven moisture content.

Controlled Environment

Advanced control systems allow for precise temperature and humidity regulation, creating an optimal drying environment for the barley.

Energy Efficiency

We incorporate energy-saving technologies to minimize power consumption, reducing the overall cost of operation.

Versatility

These machines are adaptable to different types and conditions of barley, accommodating a variety of drying needs.

Automation

The automation of the drying process reduces the need for manual labor, leading to cost savings and increased productivity.

Safety Features

We integrate multiple safety features to protect operators and ensure safe operation, such as emergency stop functions and overheating protection.

Ease of Maintenance

The design facilitates easy maintenance and cleaning, contributing to the longevity and reliability of the machine.

Hygiene

We prioritize the hygiene of the drying process to meet food safety standards and protect the quality of the barley.

Durability

High-quality materials and robust construction ensure the machine's durability and resistance to wear and tear.

Scalability

The machines can be scaled to suit different production volumes, making them suitable for a range of operations from small to large scale.

Environmental Consideration

We design the machines with environmental impact in mind, aiming to reduce emissions and waste.

Barley dryer Application

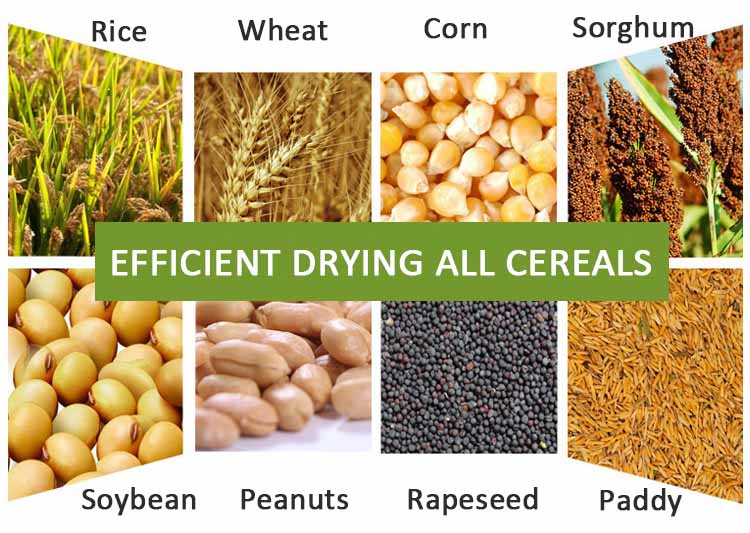

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

Barley dryer Technical Parameter

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.