agricultural dryer

An agricultural dryer is a specialized processing device for agricultural products, mainly used to dry products with high moisture content. It reduces the moisture level of the products to achieve preservation, sterilization, and moisture reduction effects.

agricultural dryer Introduction

An agricultural dryer is a specialized processing device for agricultural products, mainly used to dry products with high moisture content. It reduces the moisture level of the products to achieve preservation, sterilization, and moisture reduction effects. Agricultural dryers are widely used in the drying processes of grains, fruits, vegetables, medicinal herbs, seeds, and other agricultural products.

Main features of agricultural dryer

High Efficiency Drying

Agricultural dryers utilize advanced drying technology to efficiently remove moisture from agricultural products in a short period, ensuring uniform drying.

High Degree of Automation

Modern agricultural dryers are equipped with automated control systems, enabling automatic feeding, temperature regulation, and moisture removal. This reduces the complexity of manual operations and increases work efficiency.

Low Energy Consumption

Agricultural dryers are designed with energy efficiency in mind. They use high-performance heating equipment and optimized air duct designs to minimize energy consumption while maintaining effective drying, thereby reducing operating costs.

Environmentally Friendly

Agricultural dryers focus on environmental protection through effective exhaust treatment systems and efficient heat recovery devices. These features reduce pollutant emissions and protect the environment.

Multifunctionality

Agricultural dryers are multifunctional and capable of drying various types of agricultural products, such as grains, vegetables, fruits, and medicinal herbs. Their versatility makes them widely applicable.

Easy Operation

The user-friendly design of agricultural dryers ensures easy operation and maintenance. They typically feature intuitive control interfaces and intelligent control systems, allowing users to operate them without extensive training.

Durability

Manufactured with high-quality materials, agricultural dryers are sturdy, corrosion-resistant, and capable of withstanding high temperatures. They undergo rigorous quality checks and testing, ensuring reliable performance even in harsh environments.

Excellent Drying Performance

Agricultural dryers use scientific drying principles and advanced drying processes to preserve the original nutritional content and quality of the agricultural products. The dried products retain their color, aroma, and taste.

Controllable Temperature

Equipped with precise temperature control systems, agricultural dryers can adjust drying temperatures according to the specific needs of different agricultural products, ensuring stable and controllable drying conditions.

Safety and Reliability

Agricultural dryers are designed and manufactured following strict safety standards and are equipped with multiple safety protection devices, such as overheating protection and leakage protection, ensuring safe operation.

Main structure of agricultural dryer

Drying Chamber

This is where the agricultural products needing drying are placed. It can be stationary or mobile, often equipped with trays, racks, or conveyor belts for product placement and movement.

Heating System

Provides the heat source for drying. Heating methods include electric, gas, diesel, or hot air furnace heating. The system generates heat through combustion or electric heating and transfers it into the drying chamber.

Air Duct System

Distributes hot air evenly throughout the drying chamber to ensure uniform drying of agricultural products. Components include fans, ducts, and dampers. Fans introduce hot air into the chamber, while ducts and dampers control the direction and flow of the air.

Temperature Control System

Monitors and regulates the temperature inside the drying chamber to maintain stable and controllable drying conditions. It typically includes temperature sensors, controllers, and a control panel to automatically adjust the heating system based on set temperatures.

Dehumidification System

Removes moisture generated during the drying process from the drying chamber to maintain a dry environment. Components include dehumidification fans, ducts, and valves to effectively expel moisture.

Control System

Acts as the brain of the agricultural dryer, automating the entire drying process. It includes PLC controllers, human-machine interfaces (HMIs), and various sensors to centrally control and monitor heating, air ducts, temperature, and dehumidification systems.

Conveyor System

Some agricultural dryers feature conveyor systems to automatically transport agricultural products in and out of the drying chamber. These can be belt conveyors, chain conveyors, or drum conveyors, enhancing automation and efficiency.

Framework Structure

Provides the foundational support for the entire dryer, typically made of steel or other sturdy materials to ensure stability and durability.

Filtering System

Filters incoming air to prevent dust and impurities from entering the drying chamber, ensuring the quality of dried agricultural products. Components include air filters and filter screens.

Safety Devices

Equipped with various safety devices such as overheat protection, leakage protection, emergency stop switches, etc., to ensure operational safety and quickly respond to emergencies.

Main advantages of agricultural dryers

High Efficiency and Speed

Agricultural dryers utilize advanced drying technologies and equipment to quickly remove moisture from agricultural products, thereby enhancing drying efficiency and reducing drying cycles.

Energy Saving and Environmental Protection

By optimizing design and employing efficient heating systems, agricultural dryers minimize energy consumption, lowering production costs. They also use eco-friendly materials and equipment to reduce environmental impact.

High Drying Quality

Agricultural dryers preserve the color, aroma, and nutritional content of agricultural products, ensuring consistent and reliable drying outcomes.

Versatility

They are capable of drying various types of agricultural products, including grains, vegetables, fruits, and medicinal herbs, making them highly versatile.

Ease of Operation

Equipped with intelligent control systems, these dryers are easy to operate, reducing manual intervention and improving operational efficiency.

High Automation

Integrated with automated control systems, agricultural dryers facilitate automatic feeding, temperature control, and moisture removal, minimizing labor costs.

Stability and Reliability

Built with robust and durable structures, agricultural dryers undergo rigorous quality inspections and testing, ensuring stable operation in diverse environments.

High Safety Standards

They feature multiple safety protection devices such as overheat protection and leakage protection, ensuring the safety of operators and equipment.

Cost-effectiveness

By extending the storage life of agricultural products and enhancing market competitiveness, agricultural dryers deliver economic and social benefits.

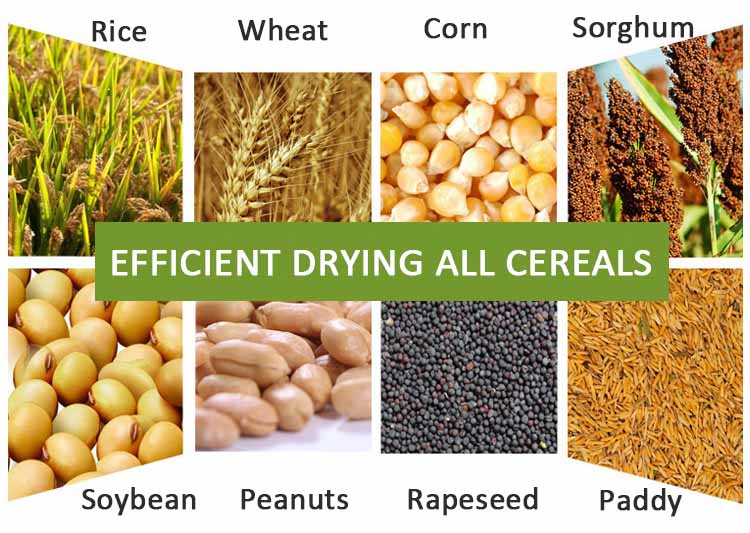

Agricultural dryer Application

The agricultural dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

Working Principle

The paddy crops are input from the top of the tower through the bucket elevator, and through the distribution device to ensure that the equipment is always in a full load state during operation.

The induced draft fan introduces the hot air into the inside of the tower body, and the rice crops are combined with the bottomless V-shaped baffles that are turned inward, and the multi-row V-shaped baffles are arranged staggered for processing, so that the rice crops can be mixed with the hot air, and the water vapor generated is discharged from the dryer exhaust system

agricultural dryer Machine Technical Parameter

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |||

| Dryer type | Batch type recirculating mixed flow drying | |||||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |||

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |||

| Overall weight(kg) | 5000 | 6000 | 9500 | |||

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |||

| Power(kw) | 8.7 | 8.7 | 13.5 | |||

| Bunner | Type | Indirect Type | ||||

| Ignition method | Manual Ignition | |||||

| Fuel consumption (kg/h) | ≤25(coal)

30-40(rice husk) |

≤25(coal)

30-40(rice husk) |

≤30(coal)

70-120(rice husk) |

|||

| Fuel | Coal, rice husk, wood chips, gas, diesel, etc | |||||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||||

| Safety Equipment | Temperature control, Electrical overload protection, Leakage Protection | |||||

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.